From BSP to ORFS, have a read to find out about thread patterns!

There are many different variations of thread when it comes to hose fittings. We have compiled some information and measurement charts on a few of the more common threads that we see here at ABCo.

British Standard Pipe Thread or BSP is one of the most widely recognised thread patterns. Whilst most common in the UK, BSP has been adopted by many countries worldwide, particularly in Europe. There are two main types of BSP thread: British Standard Pipe Parallel Thread (BSPP) and British Standard Pipe Tapered Thread (BSPT).

Please see below for the pattern measurement chart.

| Size | Dash Size | TPI | BSPP Male O.D (mm) | BSPT Male O.D (mm0 | BSPP Female I.D (mm) | BSPT Female I.D (mm) |

| ⅛” | -2 | 28 | 9.6 | 9.5 | 8.6 | 8.4 |

| ¼” | -4 | 19 | 13 | 12.8 | 11.9 | 11.2 |

| ⅜” | -6 | 19 | 16.5 | 16.3 | 15.2 | 14.7 |

| ½” | -8 | 14 | 20.8 | 20.4 | 19.1 | 18.3 |

| ⅝” | -10 | 14 | 22.8 | 22.5 | 20.8 | 20.6 |

| ¾” | -12 | 14 | 26.3 | 25.9 | 24.6 | 23.9 |

| 1” | -16 | 11 | 33.1 | 32.6 | 30.7 | 29.7 |

| 1 ¼” | -20 | 11 | 41.8 | 41.1 | 39.4 | 38.6 |

| 1 ½” | -24 | 11 | 47.7 | 47 | 45.5 | 44.5 |

| 2” | -32 | 11 | 59.5 | 58.6 | 57.4 | 56.4 |

Joint Industry Council Thread or JIC, is another popular thread commonly used for hydraulic systems. Being predominantly used in North America, JIC fittings have become increasingly popular throughout the global industrial and agricultural industries.

Please see below for the pattern measurement chart.

| Size | Dash Size | Thread | Male O.D (mm) | Female I.D (mm) | Hex (mm) |

| 3.8” | 6 | 24 UNF | 9.5 | 8.6 | 14 |

| 7/16” | 7 | 20 UNF | 11.1 | 10 | 17 |

| ½” | 8 | 20 UNF | 12.7 | 11.6 | 17 |

| 9/16” | 9 | 18 UNF | 14.3 | 13 | 19 |

| ¾” | 12 | 16 UNF | 19.1 | 17.6 | 22 |

| ⅞” | 14 | 14 UNF | 22.2 | 20.5 | 27 |

| 1 1/16” | 17 | 12 UNF | 27 | 24.6 | 32 |

| 1 3/16” | 19 | 12 UNF | 30.1 | 28.3 | 36 |

| 1 5/16” | 21 | 12 UNF | 33.3 | 31.3 | 41 |

| 1 ⅝” | 26 | 12 UNF | 41.3 | 39.2 | 50 |

| 1 ⅞” | 30 | 12 UNF | 47.6 | 45.6 | 60 |

| 2 ½” | 40 | 12 UNF | 63.5 | 61.5 | 75 |

Metric fittings come in a range of standardised thread patterns and are available in both a Heavy and Light variations. Typically used in Europe, Heavy/Light Series shares many characteristics with other British threads such as BSP.

Please see below for the pattern measurement chart.

| Thread | Tube O.D Light | Tube O.D Heavy | Male O.D (mm) | Female I.D (mm) |

| M12x1.5 | 6mm/6L | N/A | 12 | 10.5 |

| M14x1.5 | 8mm/8L | 6mm/6S | 14 | 12.5 |

| M16x1.5 | 10mm/10L | 8mm/8S | 16 | 14.5 |

| M18x1.5 | 12mm/12L | 10mm/10S | 18 | 16.5 |

| M20x1.5 | N/A | 12mm/12S | 20 | 18.5 |

| M22x1.5 | 15mm/15L | 14mm/14S | 22 | 20.5 |

| M24x1.5 | N/A | 16mm/16S | 24 | 22.5 |

| M26x1.5 | 18mm/16L | N/A | 26 | 24.5 |

| M30x2.0 | 22mm/22L | 20mm/20S | 30 | 28 |

| M36x2.0 | 28mm/28L | 25mm/25S | 36 | 34 |

| M42x2.0 | N/A | 30mm/30S | 42 | 40 |

| M45x2.0 | 35mm/35L | N/A | 45 | 43 |

| M52x2.0 | 42mm/42L | 38mm/38S | 52 | 50 |

ORFS or O-Ring Face Seal, is another popular type of fitting thread that is used in many OEM machines worldwide. Popular for its high performance in creating and maintaining a high-pressure seal as well as having good vibration resistance.

Please see below for the pattern measurement chart.

| Size | Dash Size | Thread | Male O.D (mm) | Female I.D (mm) | Hex (mm) |

| 9/16” | 9 | 18 UNF | 14.2 | 13 | 19 |

| 11/16” | 11 | 16 UNF | 17.5 | 15.9 | 22 |

| 13/16” | 13 | 16 UNF | 20.6 | 19.1 | 24 |

| 1” | 16 | 14 UNF | 25.4 | 23.8 | 30 |

| 1 3/16” | 19 | 12 UNF | 30.1 | 28.2 | 36 |

| 1 7/16” | 23 | 12 UNF | 36.5 | 34.2 | 41 |

| 1 11/16” | 27 | 12 UNF | 42.9 | 40.5 | 50 |

| 2” | 32 | 12 UNF | 50.8 | 48.8 | 60 |

Well, we can manufacture and assemble many variations of hose from our facilities in Nottinghamshire. We keep plenty of fittings in stock up including some of the patterns we have mentioned in this article.

Should you require a valve or fitting, then you can browse our Hose, Couplings & Valves range! If you would like a replacement hose assembled you can get in touch with us via phone or email.

You can either call us on 01636 812 674, email sales@abcohydraulics.com, message us via social media or visit our trade counter.

You can find our premises at Mill Park, Southwell, Nottinghamshire, NG25 0ET.

As well as hose assemblies, we produce high- quality products such as power packs and high pressure pumps. We manufacture bespoke cylinders and distribute premium garage equipment, including the MEGA product range.

We also design and manufacture a range of commercial pit jacks. For more information please give us a call!

We are pleased to announce that ABCo has joined Made in Britain! Please read all about our partnership, the organisation itself and how you can apply.

Made in Britain is the official organisation that “brings together the British manufacturing community, united with the use of the registered collective mark. The mark is protected and can only be used by members of Made in Britain that meet the criteria we set to guarantee the member is a British manufacturer”.

At ABCo, we aim to source our raw materials locally to ensure a high-quality final product and most of our ABCo manufactured products are assembled and tested at our factory in Nottinghamshire, UK.

Now that we are part of the Made in Britain scheme we can make use of the official mark as well as having access to a directory of fellow British manufacturers.

We have already utilised the registered mark across some of our manufactured product range and documentation which you may have seen. We have also updated our dedicated profile which you can view on their own website.

We are glad to be part of such a welcoming community and look forward to continuing our partnership with Made in Britain.

Should you require any more information or are interested in applying, please have a look at their website: https://www.madeinbritain.org/apply

You can follow this link which will direct you to the official Made in Britain site - https://www.madeinbritain.org/

You can either call us on 01636 812674, email sales@abcohydraulics.com, message us via social media or visit our trade counter. Our trading office is at Mill Park, Southwell, Nottinghamshire, NG25 0ET

We produce high- quality products such as pit jacks, cylinders, power packs and high pressure pumps. We also distribute premium garage equipment, including the MEGA product range. For more information please give us a call!

Learn all about the regulations regarding lifting equipment and how we can get your pit jack back up to standards.

You are required to regularly maintain and test your pit jack by the Lifting Operations & Lifting Equipment Regulations 1998 (LOLER).

In the UK, LOLER requires that lifting equipment such as pit jacks must be of adequate strength and stability. The regulations state that all lifting equipment should be fit for purpose, appropriate for the task, suitably marked and, in many cases, subject to statutory periodic 'thorough examination'. During this examination period, any defects (which are or could potentially become a danger to people) will be found and reported.

Lifting equipment must be thoroughly examined in a number of situations. Your equipment must be checked before the first use, if you install at another site or if it has been subject to conditions liable to result in danger. Following the examination, any defects can be identified and if so, a service can be booked.

Our Pit Jacks are always built using high-quality steels, ensuring strength and durability. Should you require a repair, we can offer a full factory service and complete refurbishment of your Pit Jack to ensure it complies with regulations above. Following the refurbishment, we will test your Pit Jack to confirm the performance and quality standards have been met.

Please contact us or visit Pit Jack Repair & Service for more information.

You can follow this link which will direct you to the GOV.UK official LOLER page - www.hse.gov.uk/work-equipment-machinery/loler.htm

You can either call us on 01636 812674, email sales@abcohydraulics.com, message us via social media or visit our trading office.

Our trading office is at Mill Park, Southwell, Nottinghamshire, NG25 0ET

As well as our Pit Jack range, we design and manufacture high-quality products such as standard and bespoke hydraulic cylinders, high pressure pumps and power packs. All of which we can repair and service ourselves from our factory in Nottinghamshire.

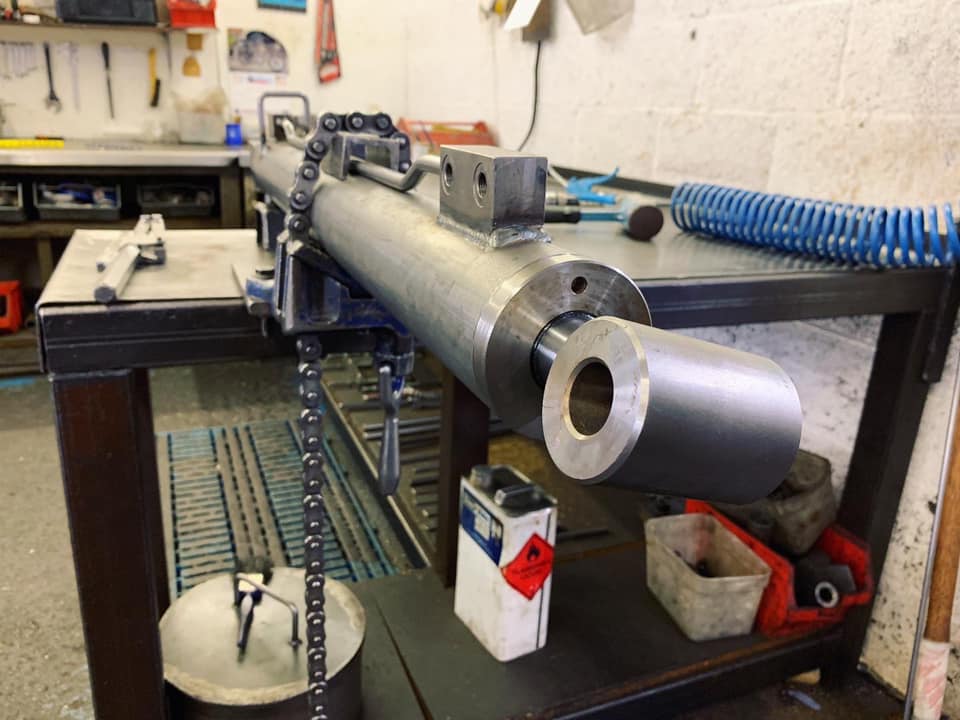

Want to know how we repair hydraulic cylinders and replace hose assemblies? Explore our guide to discover all the ins and outs of our quick and efficient repair services available in Nottinghamshire and surrounding areas.

Since 1972, we have been using our specialist expertise to repair and test all types of cylinder, including double/single acting, displacement and multi stage cylinders. We can deal with many issues, from a broken seal or bent rod to a weld crack.

We also manufacture and assemble many variations of hose. These include 1 + 2 wire and multispiral, with fitting thread patterns from BSP and JIC to light/heavy series Metric styles.

We start the ram repair process by inspecting the cylinder and assessing the damage. Once we’ve diagnosed the initial problem, we then carefully strip the cylinder and carry out a detailed inspection of each component.

If the repair is straightforward - such as a seal replacement - then we proceed. If the damage is more complex, we quote for the repair or replacement of any damaged parts and, subject to customer approval, carry out the necessary repairs and re-assemble.

On completion, we pressure test on our test rig to ensure the cylinder performance and quality standards have been met. All our repairs are guaranteed.

We can manufacture a hose based on given specifications or you can drop off the damaged hose to us and we’ll produce a high-quality replacement as per sample. Once we have understood your requirements, we will then manufacture the hose to suit and pressure test on our test rig.

Here at ABCo, we want to be certain that you walk away with a functioning cylinder or hose. Safety is a number one priority and we always take the risk-free approach to a repair to maximise lifespan and performance. As stated we can build to best suit your requirements. All repair work and servicing is done in an efficient manner and the highest standard of quality. Simply enquire today via telephone, email or online our contact form.

Subject to the work required, we offer a quick turnaround. We aim to complete large repairs in a few days and for smaller repairs in under 24 hours.

The cost will always depend on the level of work needed. Once we have inspected the cylinder or hose and understand all the factors (such as materials required) you’ll receive a quote.

You can either call us on 01636 812674, email sales@abcohydraulics.com, message us via social media or visit our trade counter.

Our trading office is at Mill Park, Southwell, Nottinghamshire, NG25 0ET

We design and manufacture high-quality products such as standard and bespoke hydraulic cylinders, high pressure pumps, power packs and commercial pit jacks. All of which we can repair and service ourselves from our factory in Nottinghamshire.