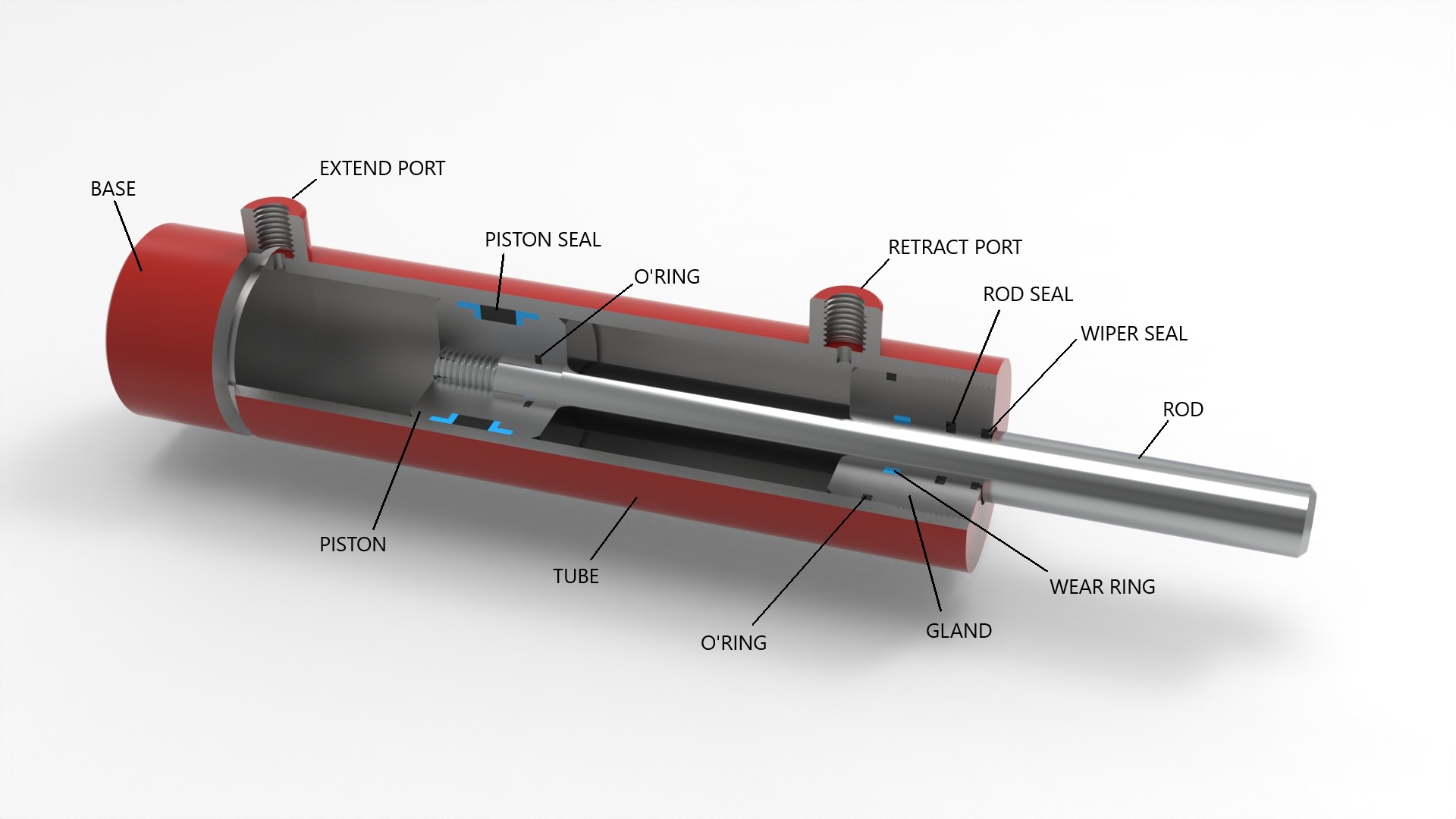

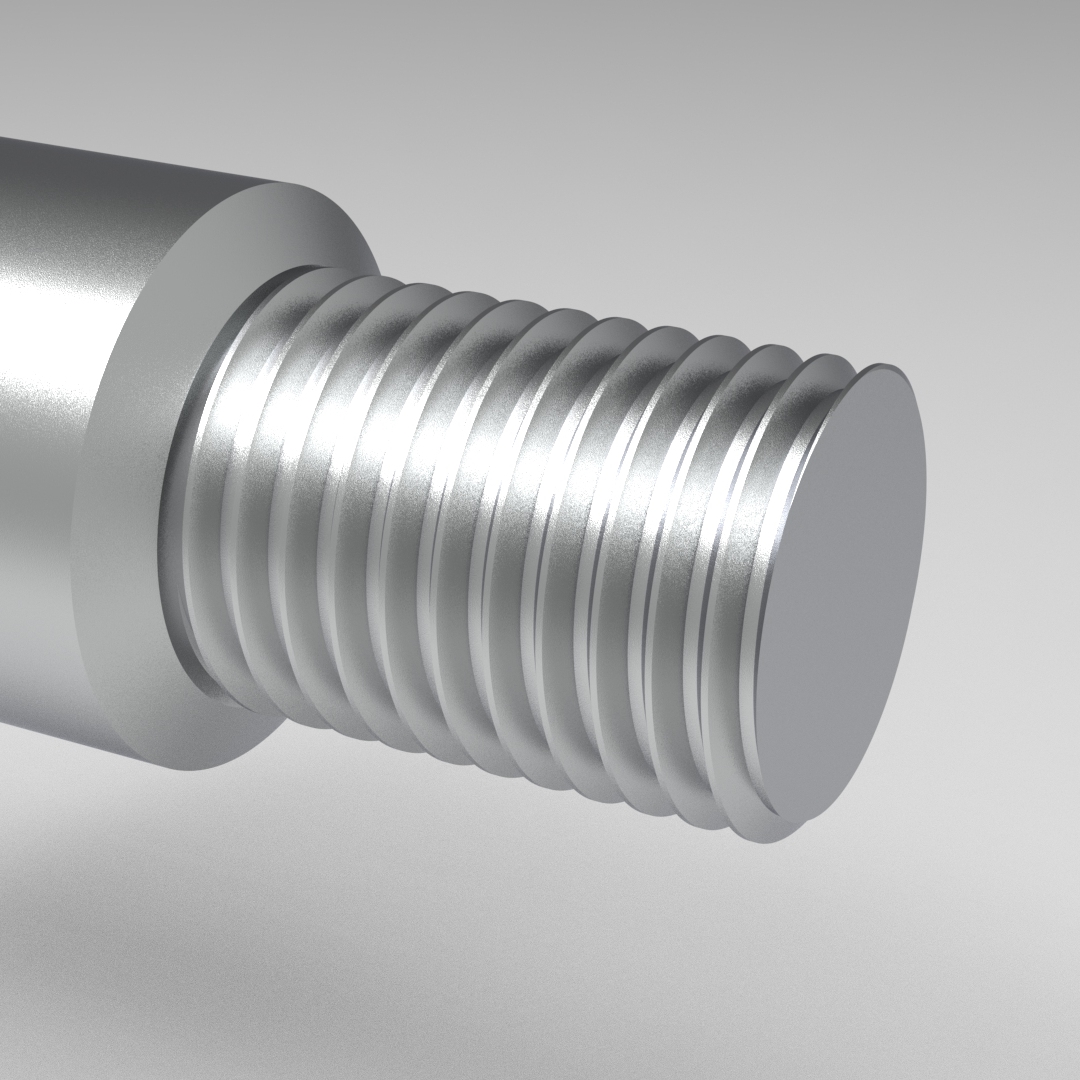

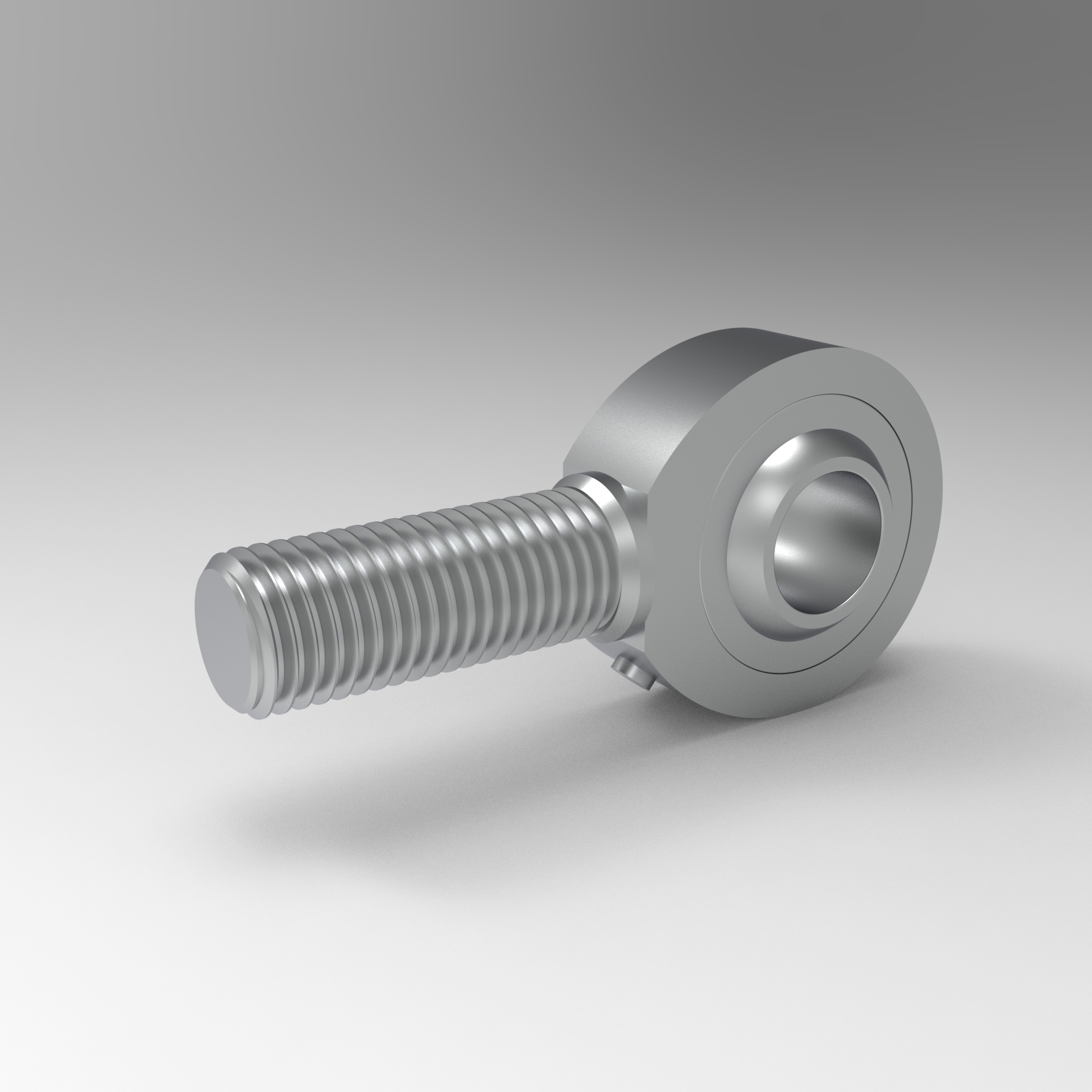

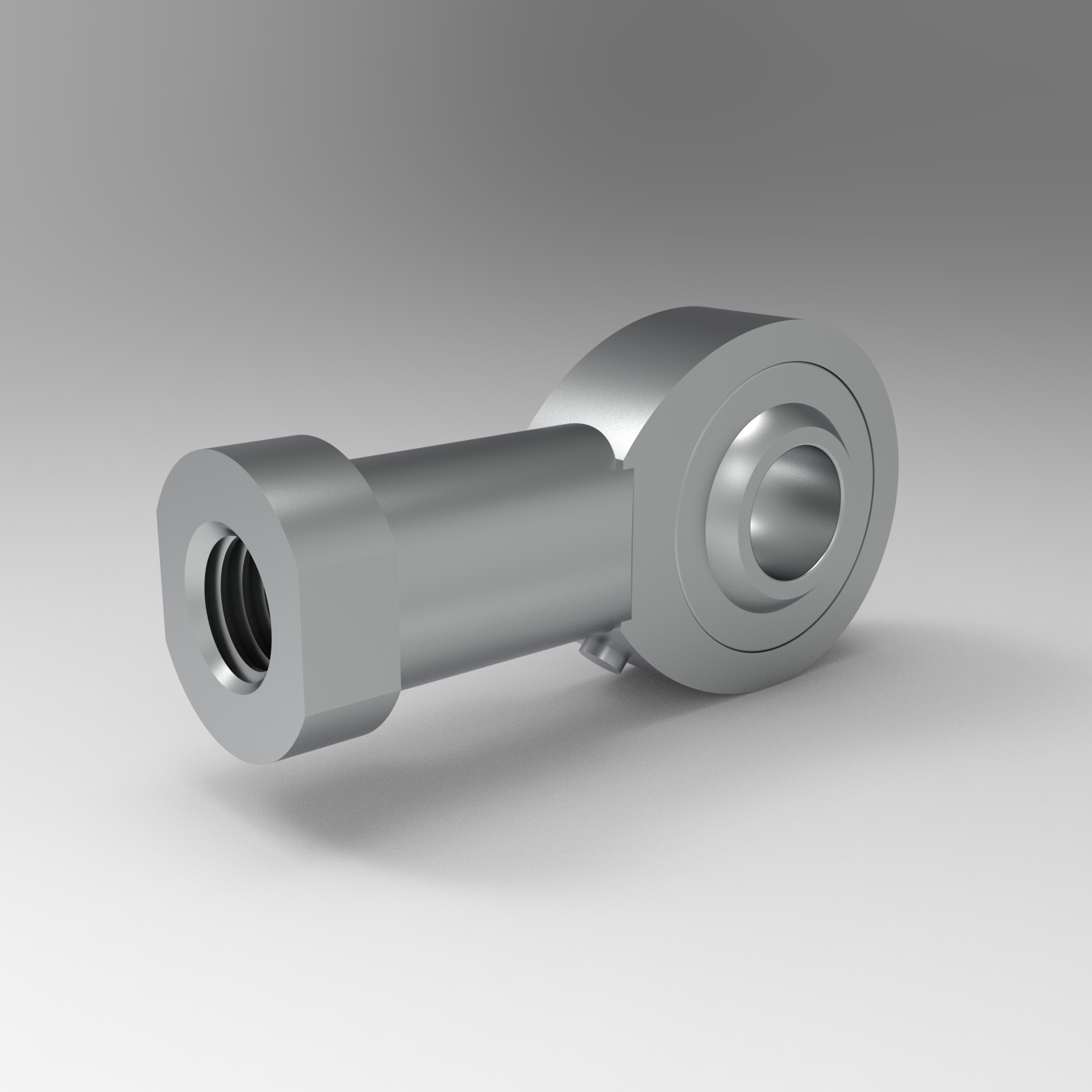

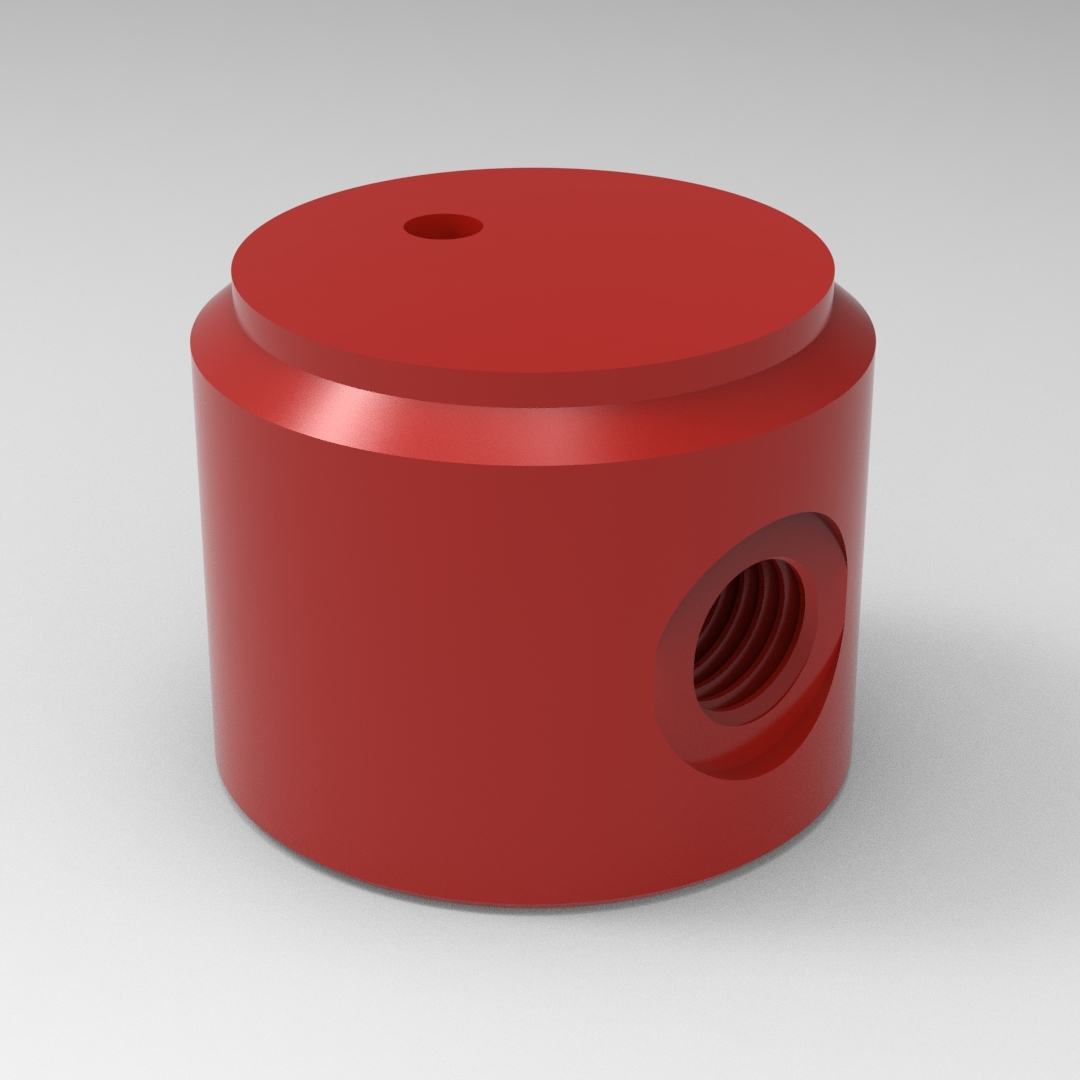

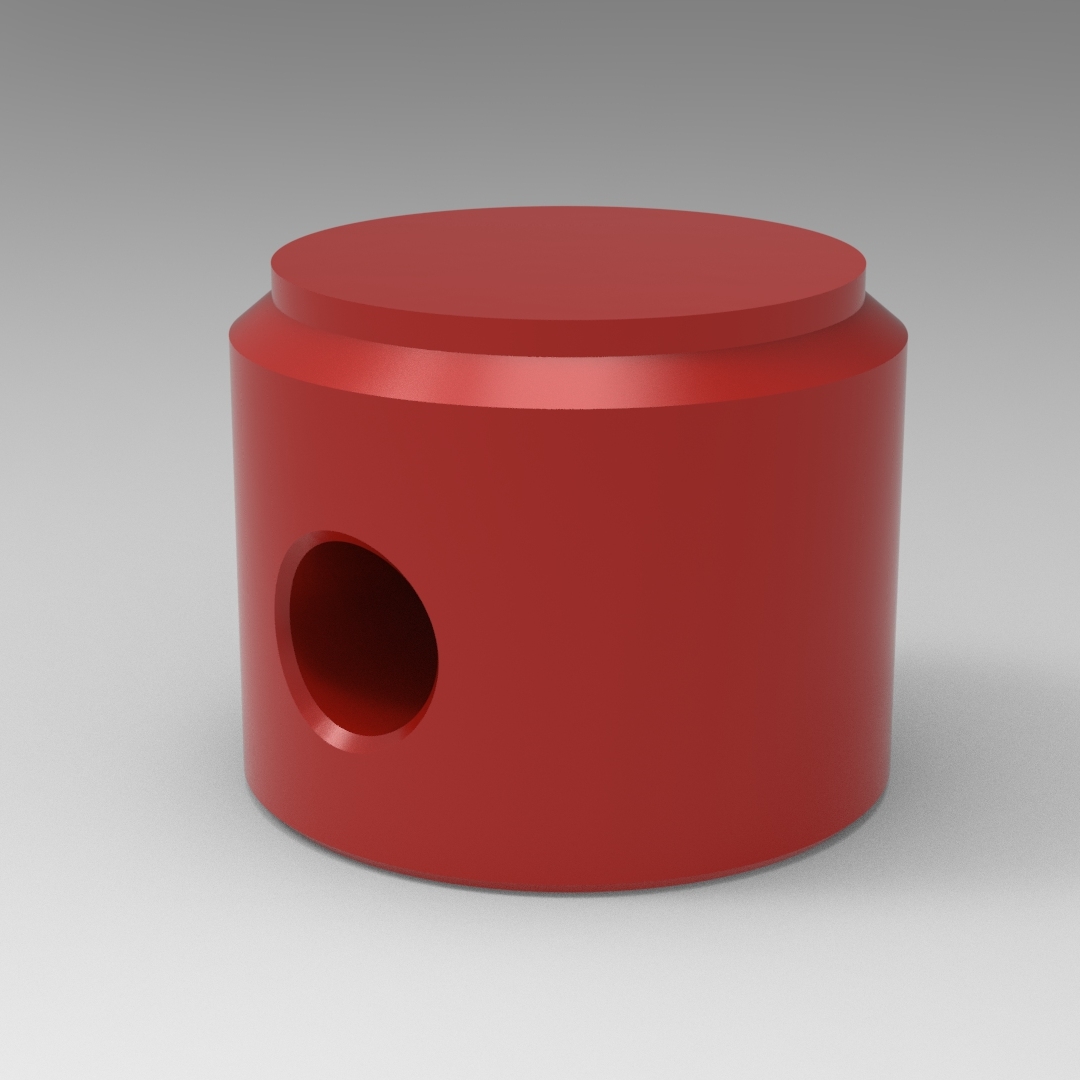

We design our hydraulic cylinders using Solid Edge CAD software and manufacture using the latest CNC machines. We are able to produce one off prototypes and single cylinders to large batch quantities. Available in different bore, rod and stroke sizes.

Initial design and quotation is completely free with no obligation.

Including options such as:

- Single/Double Acting Cylinders

- Displacement Cylinders

- Telescopic/Multi Stage Cylinders

- Through Rod Cylinders

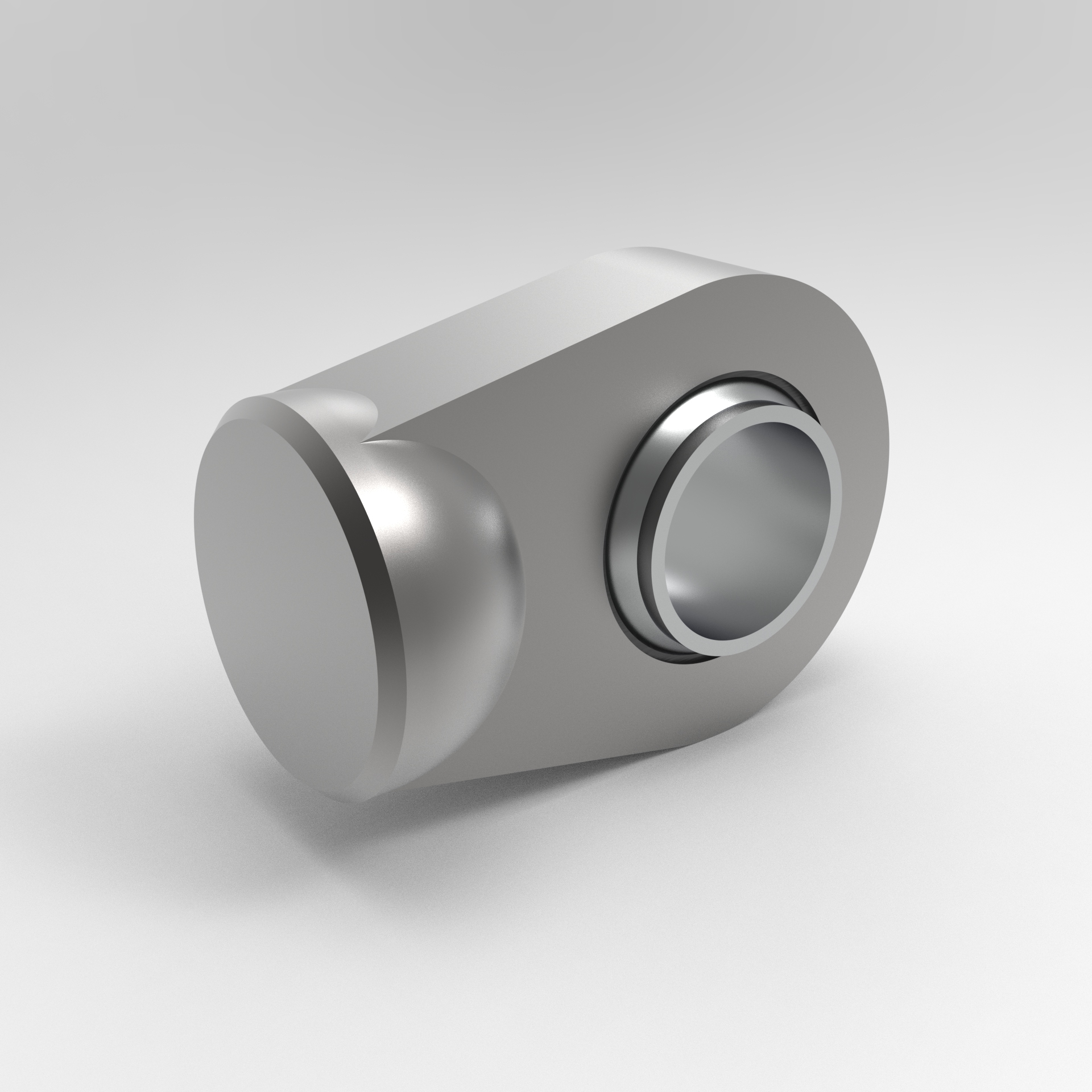

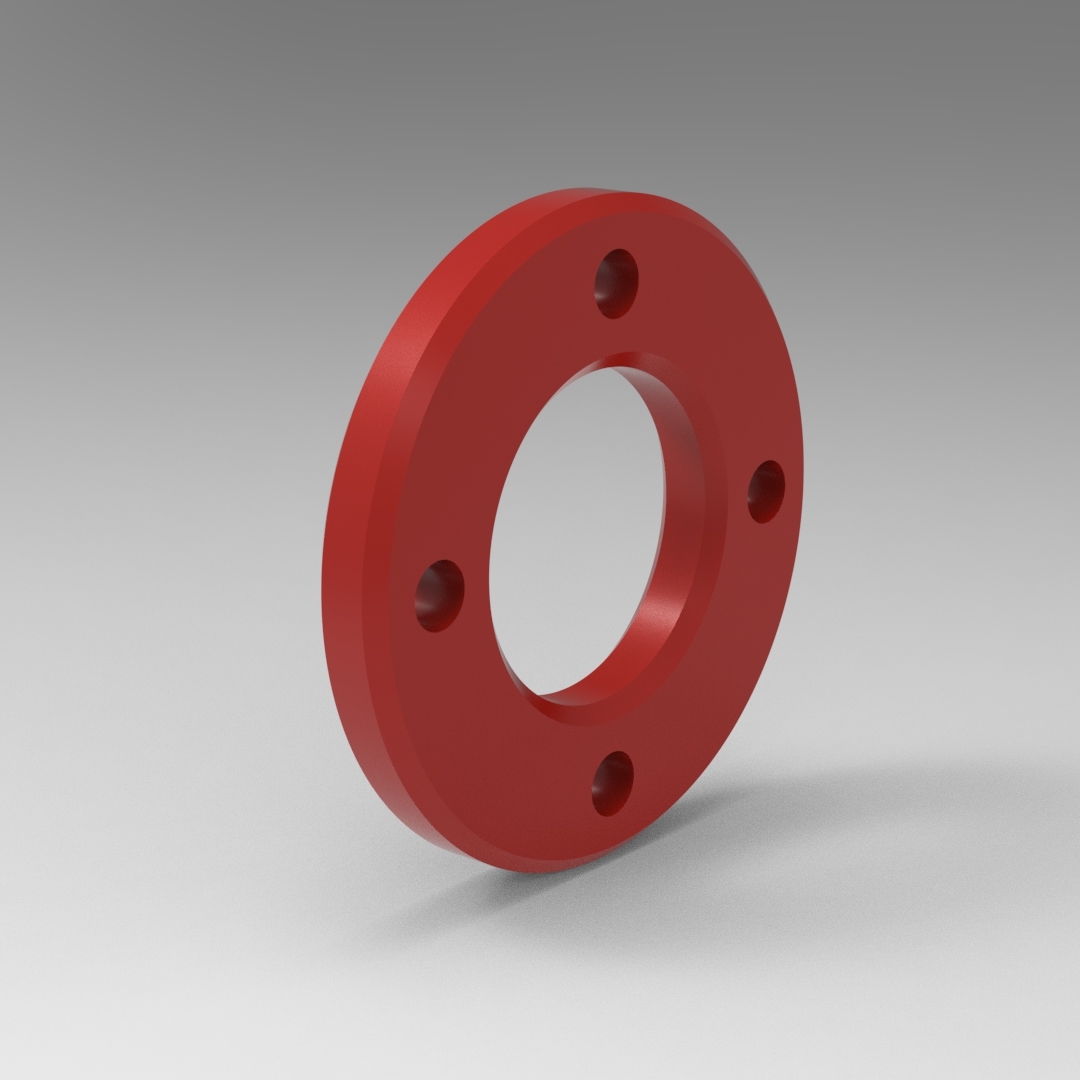

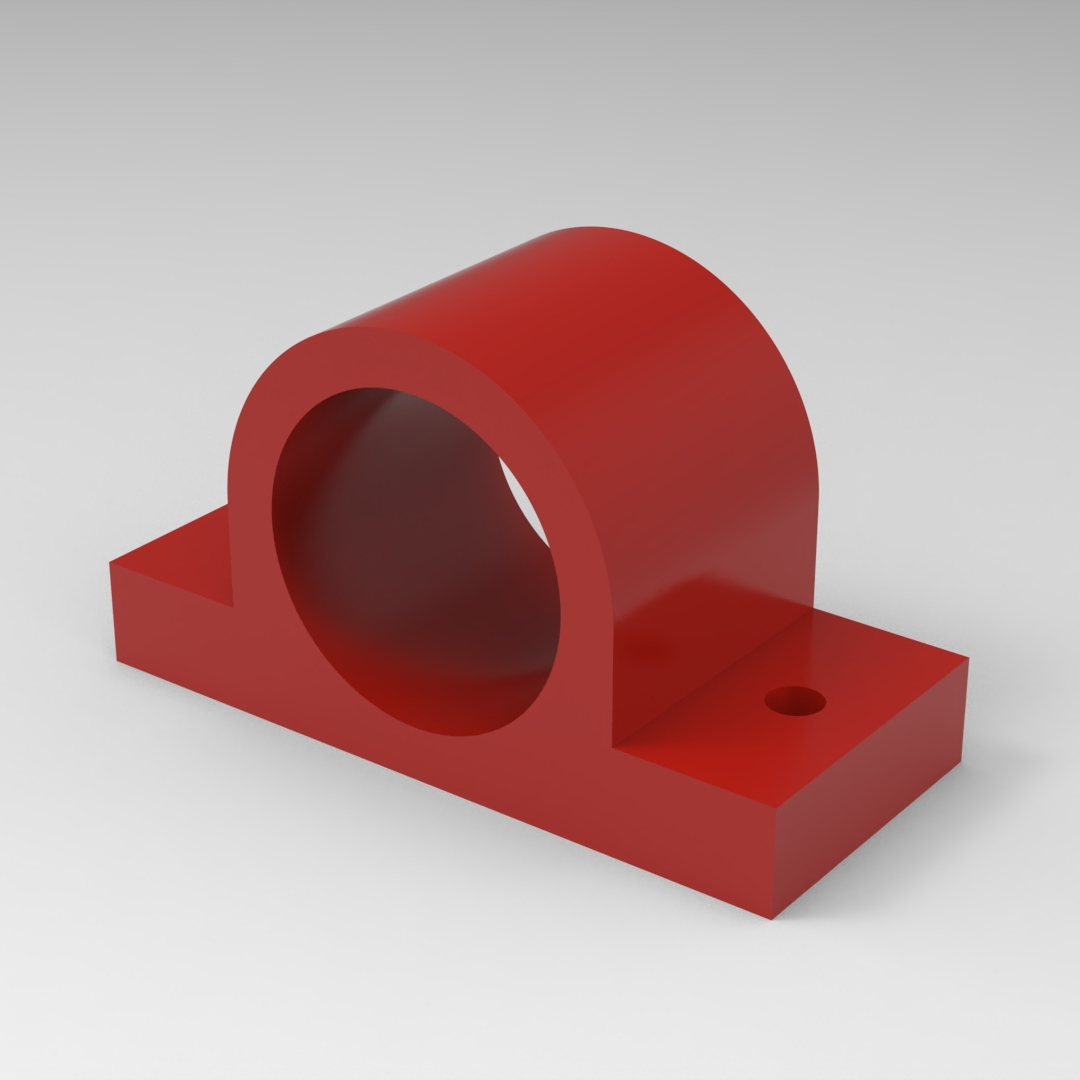

- Cylinder & Piston Rod Mounting Options & More!

ABCo has been manufacturing in the UK since 1972 and we pride ourselves on designing and producing high-quality hydraulic cylinders that are used throughout many different industries.

We supply both stock and custom-made hydraulic cylinders to various industries including the agricultural, construction, marine, mining and medical industries.

In single acting hydraulic cylinders, compressed oil is used to actuate the piston in one direction and is then retracted by the weight of the load or by an inbuilt spring. Single acting cylinders typically have one inlet port on the full bore side and a breather port on the annulus side of the piston.

Single acting cylinders are often less complex than other designs, saving on cost however force is delivered in only one direction, meaning less control as you need an external force to return the cylinder.

Double acting hydraulic cylinders deliver hydraulic oil to both sides of the piston via two inlet ports. Having an inlet port on both the full bore and annulus side of the piston allows the cylinder to be extended and retracted under the operators control. This can be used for operations such as lifting and lowering without the need of an external force to return the cylinder allowing for greater control.

Displacement hydraulic cylinders are similar to single acting cylinders as they both have a single inlet port and are load or spring returned. Essentially in a retracted state, the cylinder is filled with hydraulic oil which builds up surrounding the piston rod. As more oil is pumped into the cylinder, the volume of the piston rod will be displaced, forcing the piston rod to extend from the cylinder tube. With it having no means of retracting hydraulically, you would need an external force to return the rod to the tube.

Due to the oil filled bore and lack of breather port, in theory there should be no corrosion issues.

Double acting hydraulic cylinders deliver hydraulic oil to both sides of the piston via two inlet ports. Having an inlet port on both the full bore and annulus side of the piston allows the cylinder to be extended and retracted under the operators control. This can be used for operations such as lifting and lowering without the need of an external force to return the cylinder allowing for greater control.

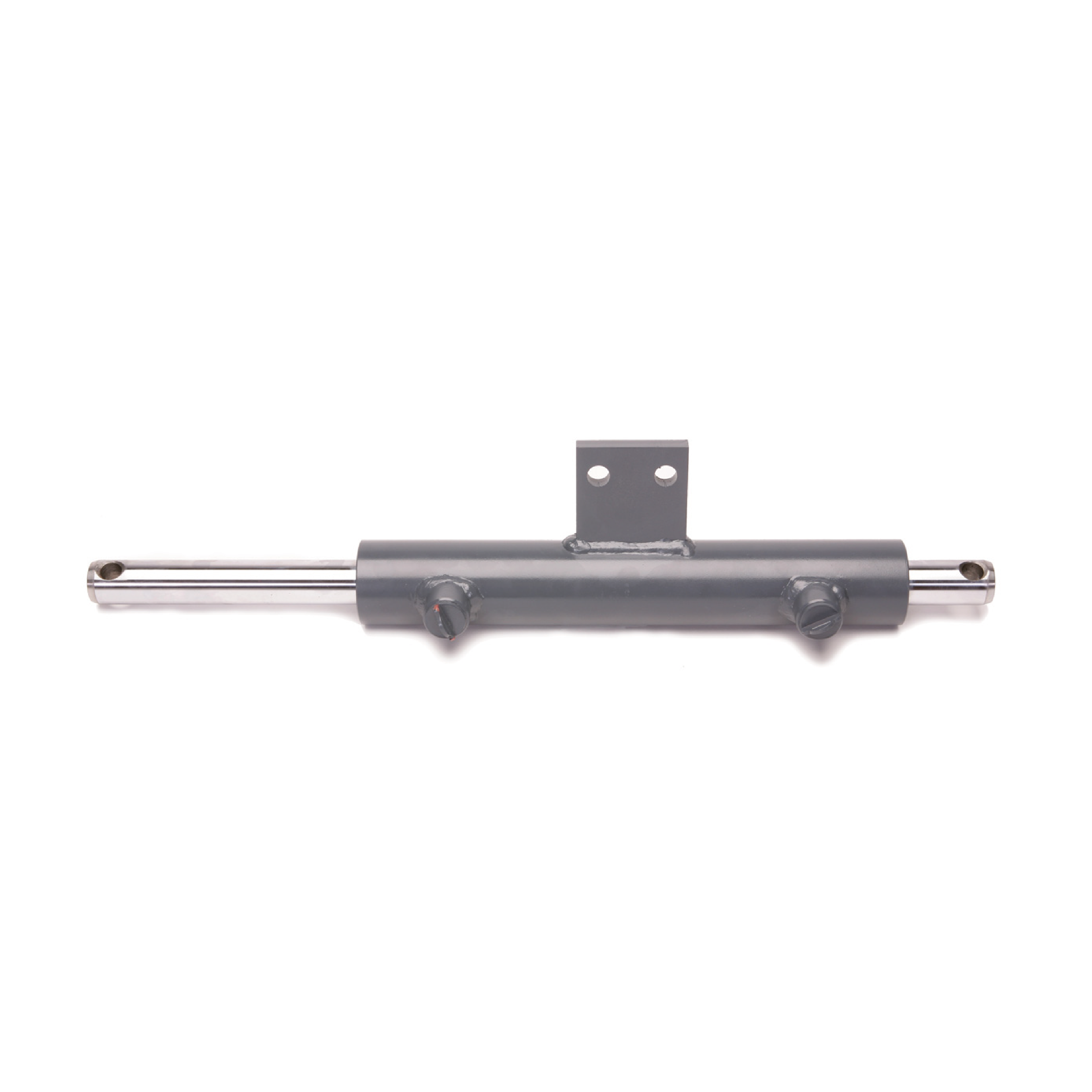

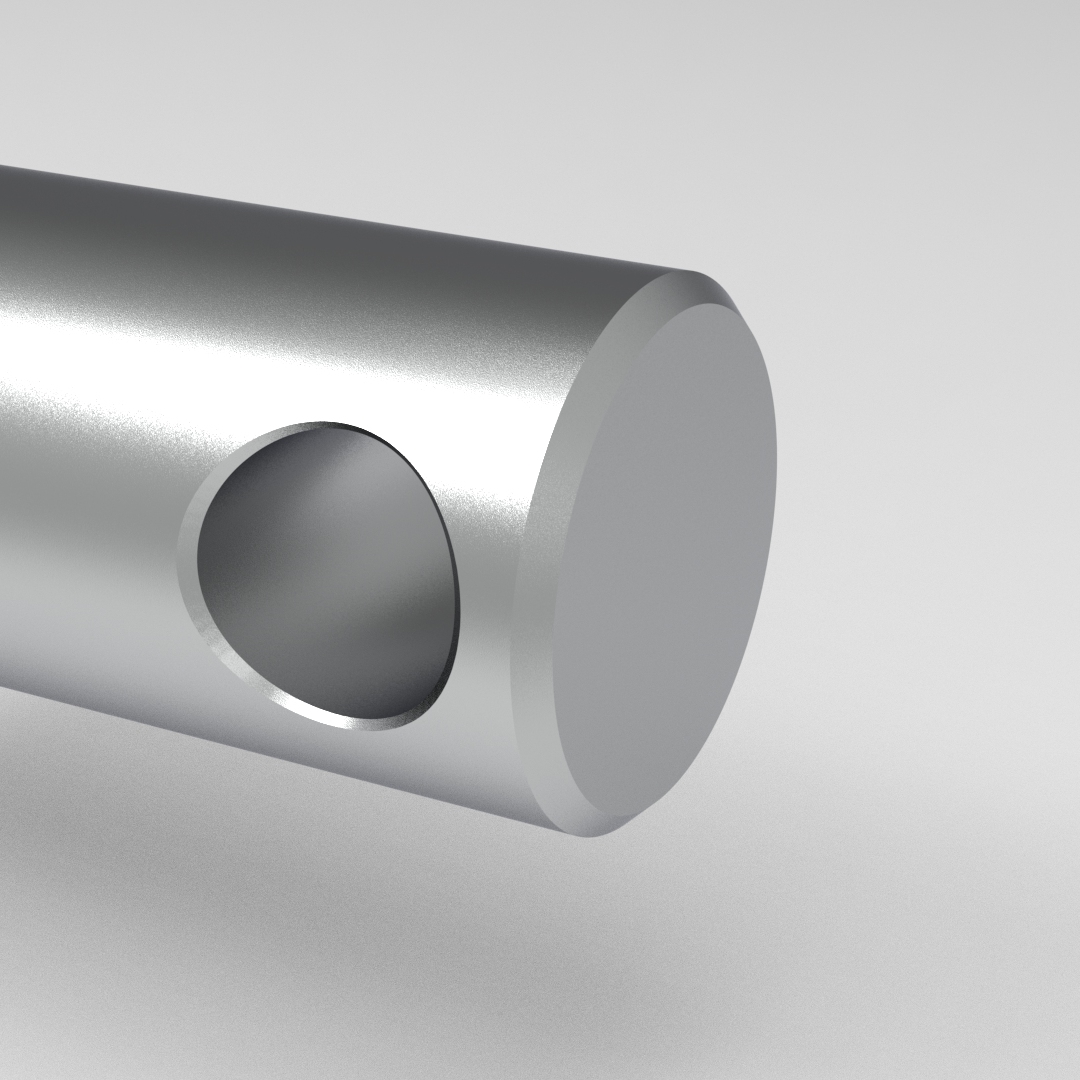

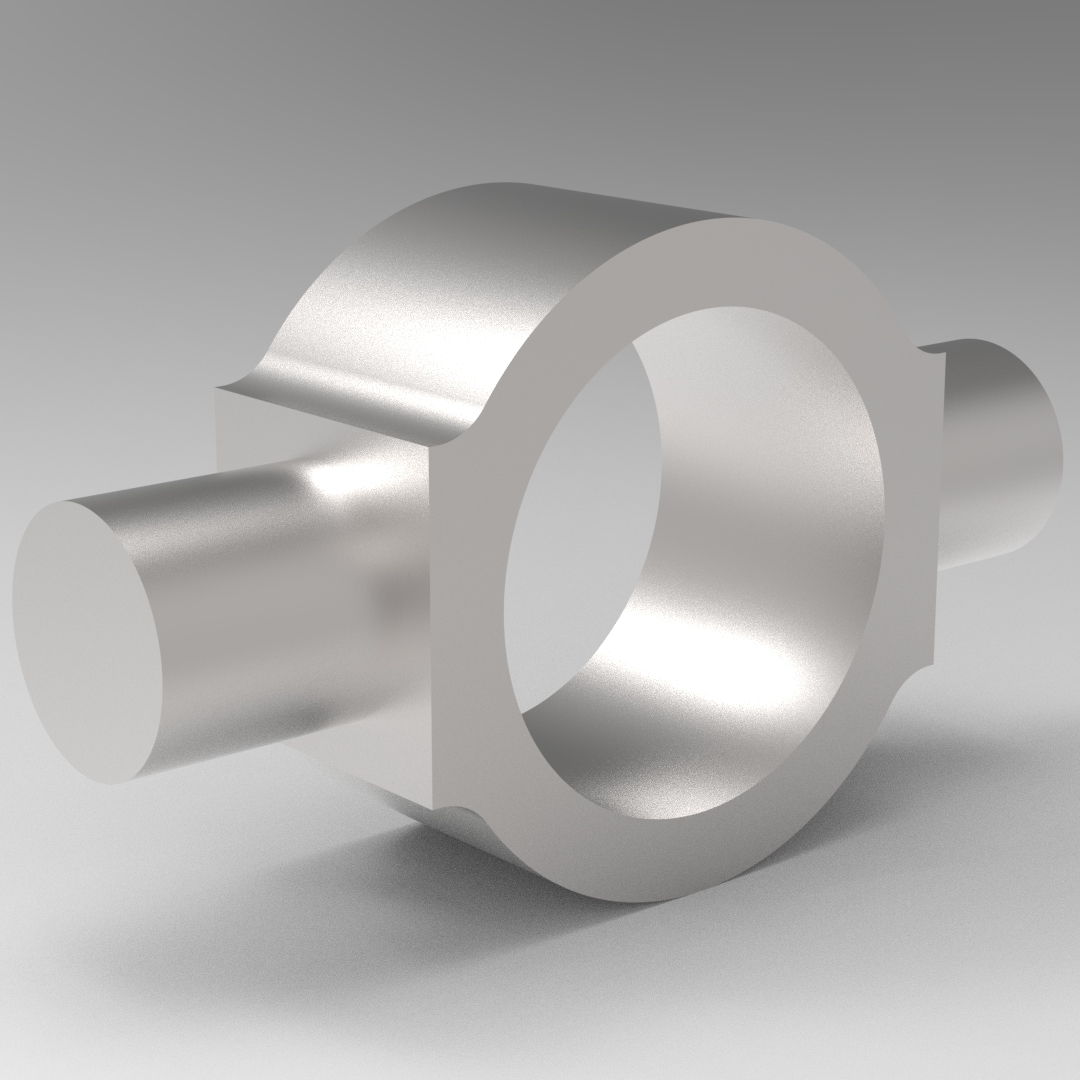

With through rod cylinders, the piston rod extends throughout the entirety of the tube and out of both sides. There is no full bore and the piston is positioned in the middle of the rod. Similar to a double acting cylinder, there is an inlet port on either side of the piston, allowing extension of the piston rod in both directions. The rod extends from one side of the cylinder and retracts into the other which makes this design perfect for operations such as vehicle steering.

Please see below for more examples of bespoke cylinders that we have previously manufactured.